The effect is based on latent heat storage, a physical transformation process that enables heat storage without a sensitive change of temperature. Therefore, the storage capacity could be increased by multiple in a tight temperature range compared with classic sensible materials.

Properties

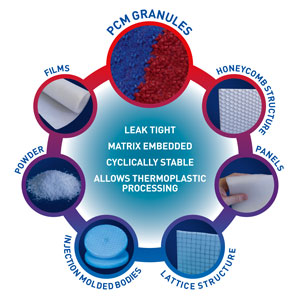

- physical bonding of the wax in a polymeric network structure (no microencapsulation)

- large heat transfer surface (granules up to 1m²/l)

- very high filling and withdrawel rate (adjustable working – melting range)

- leakproof and cycle resistant

- high heat capacity to 180J / g (50Wh / kg)

- 2-4 times the thermal capacity of water

- water or air as a heat transfer medium

- thermoplastic processability, e.g. injec-tion molding)

- different melting ranges from -4 to 82 °C

Field of applications

... as latent heat storage material...

- PCM-chips in heat buffering tanks (solar energy buffering, adsorption, cooling machines, air conditioning of buildings)

- PCM-powders in foam constructions, double walled containers

- PCM-filaments & fibres in outdoor-clothing, technical heat & cold insulation

- PCM-films & sheets in transport, packaging, medical applications, heat sinks in electronics, tarpaulins, shelters for electronics

- Storage waste heat and resure of it, e.g. home appliances, to improve energy efficiency level

Contact

smartpolymer GmbH

Breitscheidstraße 97

07407 Rudolstadt/ Thüringen

Germany

Phone: + 49 3672 - 379 - 0

Fax: + 49 3672 - 379 - 379

Email: info@smartpolymer.de

Breitscheidstraße 97

07407 Rudolstadt/ Thüringen

Germany

Phone: + 49 3672 - 379 - 0

Fax: + 49 3672 - 379 - 379

Email: info@smartpolymer.de

Download: Product-Flyer smartPCM (PDF)